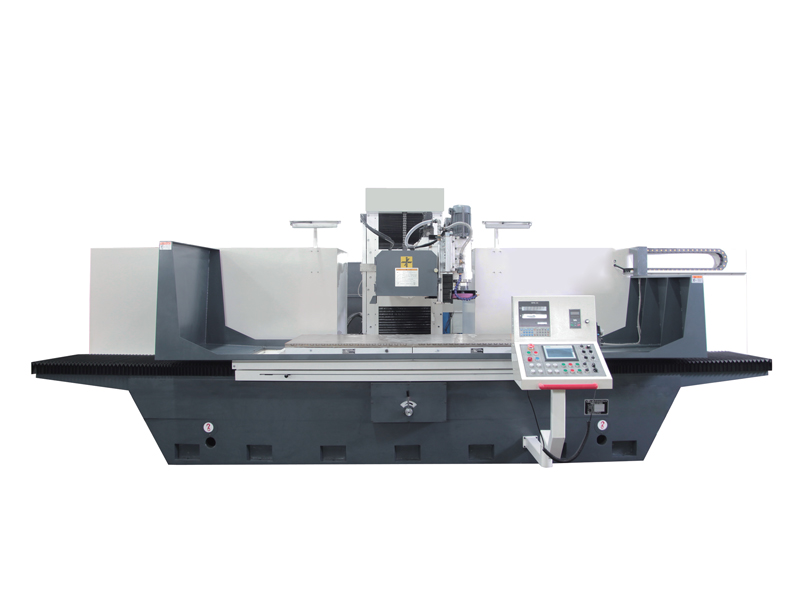

Products > FSGZ series PLC guideway grinder

| 主要參數(shù)(Specifications) | |||||

| 項(xiàng)目ITEM/機(jī)型MODEL | FSGZ80160NC | FSGZ80220NC | FSGZ100300NC | ||

| 工作范圍 | Working area | ||||

| 工作臺(tái)尺寸 | Table size | mm | 810*1600 | 810*2200 | 810*3000 |

臥磨頭磨削范圍 | grinding size by H head | mm | 810*1600*670 | 810*2200*670 | 810*3000*670 |

| 立磨頭磨削范圍 | grinding size by Vhead | mm | 680*1100*670 | 680*1700*670 | 680*2500*670 |

| 立磨頭獨(dú)立上下移動(dòng)行程 | tavelof V grindng head | mm | 210 | 210 | 210 |

| 立磨頭主軸回轉(zhuǎn)角度(手動(dòng)) | rotation (manualangle of Vspindle | ±3 | ±3 | ±3 | |

| 工作臺(tái)最大承重(含吸盤) | maxloading of table | Kg | 2000 | 2400 | 3500 |

| 各軸運(yùn)動(dòng)Moving axis | |||||

| 工作臺(tái)縱向移動(dòng)速度 | fast moving speedof table | m/min | 5~25 | 5~25 | 5~25 |

| 臥立磨頭前后快速移動(dòng)速度 | fast speed ofboh head footand baok | m/min | 0.05~2 | 0.05~2 | 0.05~2 |

| 臥磨頭前后自動(dòng)間歇進(jìn)給量 | intermittent feed of H grinding head front and back | mmit | 1~50 | 1~50 | 1~50 |

| 臥立磨頭前后電子手輪進(jìn)給量 | manual feed rate of H head front and back | mm/div | 0.005 | 0.005 | 0.005 |

| 臥立磨頭垂直快速移動(dòng)速度 | Fast speed of H head in vertical way | m/min | 0.05~2 | 0.05~2 | 0.05~2 |

| 臥立磨頭垂直自動(dòng)進(jìn)給量 | auto feed of H head in vertical waynding head | mm/t | 0.005~0.05 | 0.005~0.05 | 0.005~0.05 |

| 臥立磨頭垂直電子手輪進(jìn)給量 | mahual food ofHhead in venca wey | mmldiv | 0.005 | 0.005 | 0.005 |

| 立磨頭獨(dú)立垂直移動(dòng)速度 | movngspeed ofVgnding head m/min | 0.05~0.5 | 0.05~0.5 | 0.05~0.5 | |

| 砂輪grinding wheel | |||||

| 臥磨頭砂輪尺寸 | wheelsize ofHginding head | mm | 500×75×203 | 500×75×203 | 500×100×203 |

| 臥磨頭主軸轉(zhuǎn)速 | speed of H spindle | r/min | 960 | 960 | 960 |

| 立磨頭砂輪 | ginding wheel ofVhead | 按工藝要求(according to the tech request) | |||

| 立磨頭主軸轉(zhuǎn)速 | spinde speed ofVgindng head | r/min | 300~4000 | 300~4000 | 300~4000 |

| 電機(jī)motor | |||||

| 臥磨頭主軸電機(jī)功率 | Hgrndng head powe | kw | 18.5 | 18.5 | 18.5 |

| 立磨頭主軸電機(jī)功率 | Vgrnding head powe | kw | 2.2 | 2.2 | 2.2 |

| 總額定功率(約) | otal power | kw | 40 | 40 | 40 |

| 占地面積 | flooring space | cm | 530*450 | 650*450 | 830*450 |

| 毛重(約) | GW(about) | kg | 11000 | 13000 | 14500 |

| 注REMARK:如果磨削L型零件,可選配“工作臺(tái)防撞”裝置。 | |||||

| Optional Accessory:“worktable bump prevention system”is recommended for L type parts. | |||||

.png)